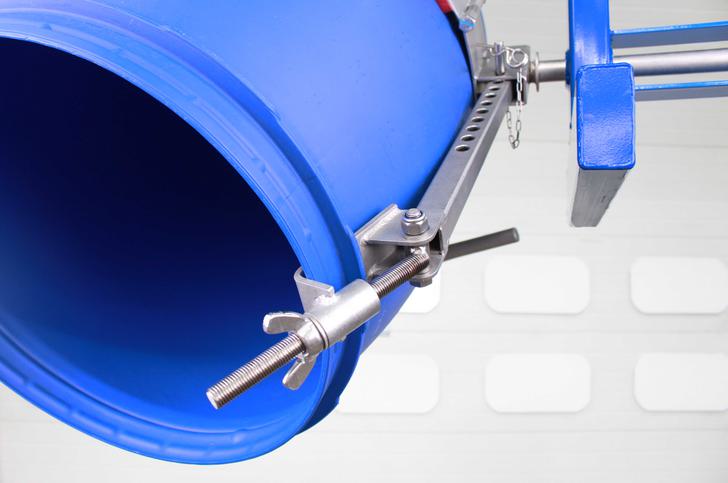

The fast-acting over-centre clamp is adjustable to allow drums from 580-600mm in diameter to be clamped (200- to 220-litre drums). Made out of stainless steel and manufactured in the UK, the securing system is extremely durable and robust. If you handle drums of varying sizes, we also supply an Overhead Drum Rotator, which is designed with a universal band, accommodating drums from as small as 50 litres right up to 220 litres.

Key product features

Rim-clamp securing system

Rim-clamp securing system

Our unique rim-locking device attaches to the upper lip of the drum to prevent drum slippage in the band assembly. MAUSER drums and other plastic drums require the use of this device to hold the drums securely. The device is not required when handling 200-litre steel drums as they can be gripped with just the rubber-lined band around the drum circumference.

Self-locking gearbox

Self-locking gearbox

A high-quality self-locking rotational gearbox ensures drums never self-rotate. Operators rotate drums by hand by turning the gearbox input handle. With an ergonomic gearbox ratio of 120:1, it is easy for any operator to decant drums in the workplace.

Large lifting pin and fork pockets

Large lifting pin and fork pockets

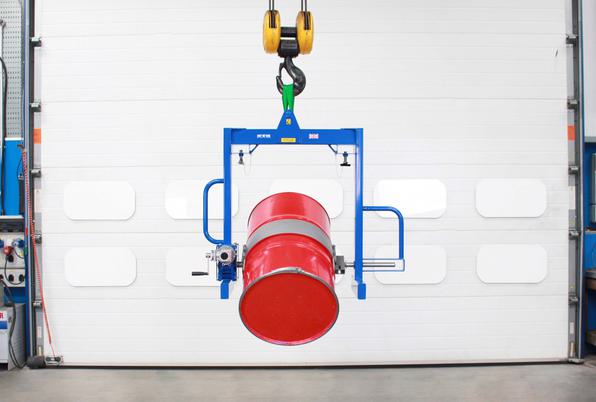

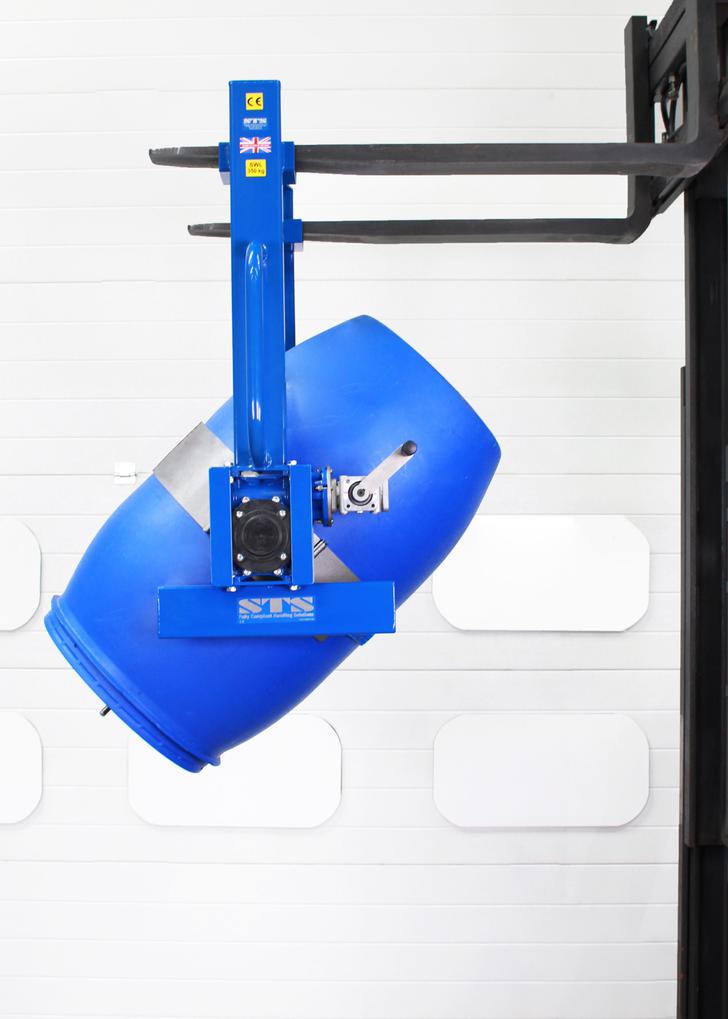

With two distinct pick-up points, the Overhead Drum Rotator (Fixed Band) is a great choice if you need a versatile drum tipper is a great choice if you need a versatile tipper. The large central lifting pin has been designed for use with an overhead crane, derrick or hoist. Fork pockets are installed beneath the top beam to allow mounting onto a stacker or forklift truck.

Drum suitability

Drum suitability

Our Overhead Drum Rotator with a fixed-radius band is suitable for drums ranging from 200- to 220-litres. We also offer a drum tipper with a universal drum band to suit drums as small as 50 litres right up to 220 litres.

ATEX / UKEX-certified for gas and dust zones 1, 2, 21 and 22 (optional)

ATEX / UKEX-certified for gas and dust zones 1, 2, 21 and 22 (optional)

An ATEX / UKEX-rated overhead drum tipper is available for use in zoned hazardous areas. Our DRU02-FB-SS-Ex is constructed from 304-grade stainless steel, this greatly reduces any thermic-strike risk. This model is suitable for gas and dust areas: Zone 1, 2, 21 and 22. All our 'Ex' rated drum handling equipment is supplied with a manufacturer’s Declaration of Conformity stating compliance with the directives and relevant British and ISO Standards.

Specification

DRU02-FB Overhead Drum Rotator (Fixed Band Band)

-

Safe working load (SWL)

350kg

-

Drum compatibility

Steel and plastic drums, 200-220 litres

-

Band assembly

Fixed rotator band with fast-acting over-centre clamp

-

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

-

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

-

Construction

Mild steel chassis, stainless steel rotator band assembly

-

Metal preparation

Grit blasted mild steel, aqua blasted and vibro-polished stainless steel parts

-

Surface finish

Primer and polyester powder coated mild steel, stainless steel is smooth and clean

-

Powder coat colour

RAL 5010 (blue)

-

Compatible with overhead crane

Yes, large lifting pin

-

Compatible with forklift truck

Yes, fork pockets included

-

Compliance

CE / UKCA

DRU02-FB-SS-Ex ATEX / UKEX Overhead Drum Rotator (Fixed Band)

-

Safe working load (SWL)

350kg

-

Drum compatibility

Steel and plastic drums, 50-220 litres

-

Drum compatibility

Steel and plastic drums, 50-220 litres (incl. MAUSER drums)

-

Band assembly

Segmented adjustable/universal band with 50mm stainless steel ratchet and polyester strap

-

Additional drum securing

Rim clamp included which grips the top edge of the drum preventing slippage

-

Rotation gearbox

Worm-wheel, self-locking with 120:1 ratio and manual handle

-

Construction

Stainless steel chassis and rotator band assembly

-

Metal preparation

Aqua blasted and vibro-polished stainless steel parts

-

Surface finish

Smooth clean stainless steel finish

-

Compatible with forklift truck

Yes, fork pockets included

-

Compatible with overhead crane

Yes, large lifting pin

-

Compliance

CE / UKCA

ATEX / UKEX (zones 1, 2, 21, 22)

Optional features

ATEX / UKEX option

We can offer an ATEX / UKEX version of this drum rotator model, suitable for use in zone 1, 2, 21 and 22 environments.Stainless-steel model

We can offer a 304-grade stainless steel unit with a aqua blasted smooth clean finish. These units are suitable for clean rooms and Good Manufacturing Practice (GMP) areas.Load cell weighing system

We are able to offer an Overhead Drum Rotator with an integrated load-cell. Weigh drums at the same time as you decant from them using the unique system.Sale or return

In the UK we can supply certain equipment on a sale-or-return basis, meaning you can use a unit on-site for seven days with no obligation to buy it once the trial period is up. Find out more here.

Technical specification

Instruction manual

Contact Us

Do you have a manual handling issue we could solve? We’d be happy to discuss any handling concerns and advise on the most suitable STS equipment. You can talk to us via telephone, email and social media.

Drum Rotators / Tippers

Tipping drums is an essential part of many industrial processes. Our drum rotators provide a safe way to lift and tip various drum types and sizes, and we can customise each rotator to suit your exact needs.