Made from stainless steel plates and machined bushes our automatic drum gripper allows operators to connect the barrel stacker to a variety of different drum types. The gripper will handle steel and plastic 100- to 220-litre drums providing they weigh more than 50kg; the drum must have some weight to force the gripper to close (won't grip empty drums).

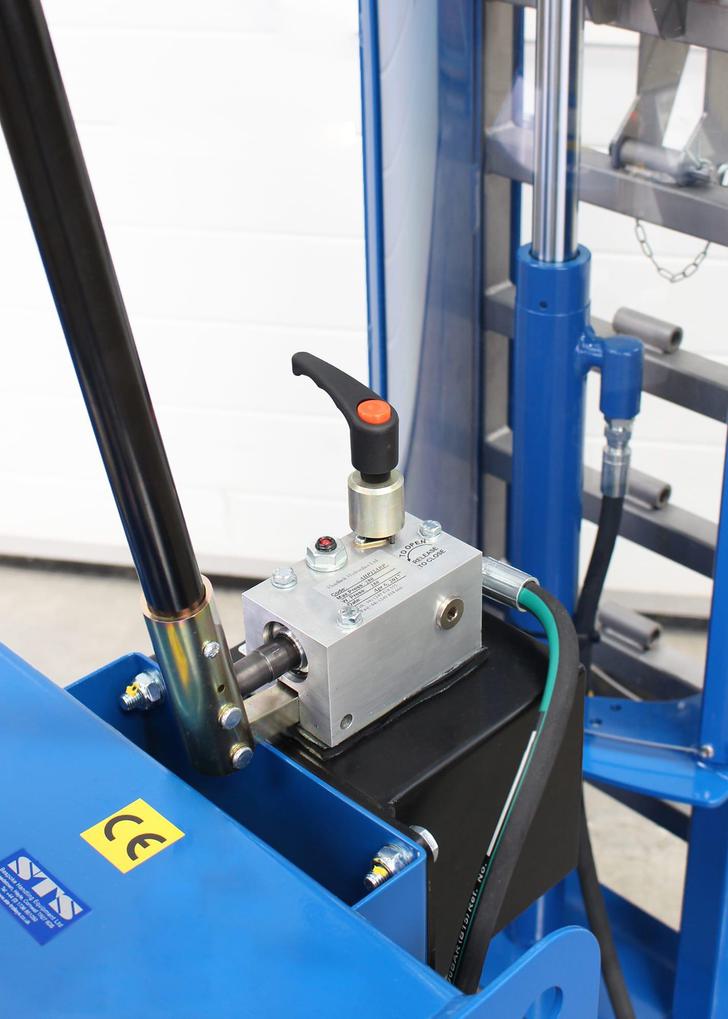

To use the gripper the operator simply raises the catch up until it is level with the top rim of the drum, they then push the unit forwards so the top hook goes over the edge of the drum, the unit's black handle is then pumped to raise the gripper which simultaneously closes the jaws over the lip of the drum. The operator keeps pumping the handle until the drum is at the desired height.