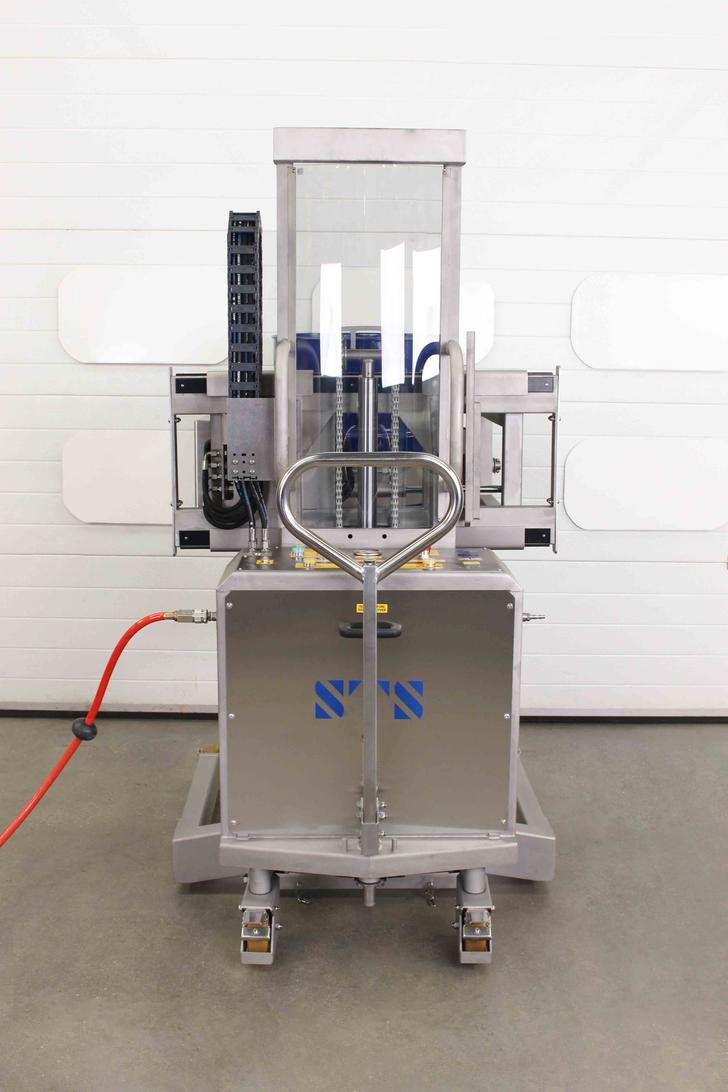

Featuring powered clamp, lift and rotation, this model is a great fit for those companies looking for efficiency gains in departments that handle drums. All our units are installed with fully-compliant lift circuits; our in-house qualified engineers install all our units with the mandatory safety features and emergency stops to keep operators safe during use.

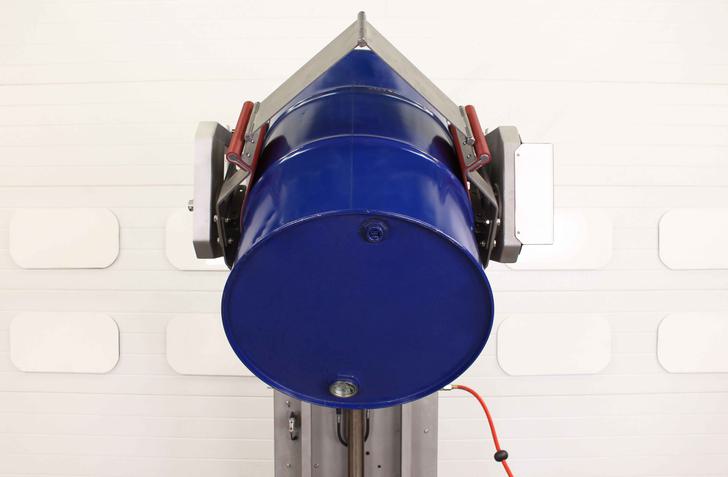

This stainless steel power-clamp drum tipper also features a clamp pressure gauge to allow operators to monitor the clamp pressure during use. Additionally, the hydraulic rams are protected by burst valves should a hose or fitting be damaged during use.