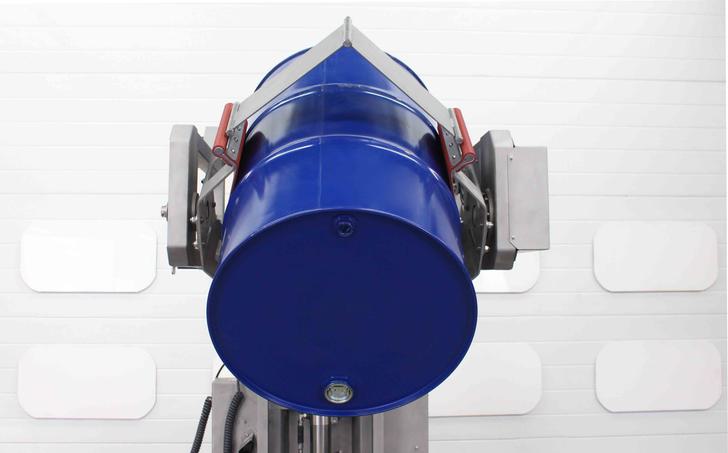

We design, build and test all our power drive drum tippers in our UK manufacturing facility. Sourcing the highest quality parts makes certain that all our units require the minimum of maintenance.

Electric

Suitable for safe areas, this fully-powered drum tipper makes use of an onboard battery bank along with two DC electric motors; one for drive and one for clamp/lift/rotation. When the unit is not in use operators connect a mains power lead to the built-in charger to ensure the unit remains fully charged.

Pneumatic

Our pneumatic units can be certified for use in ATEX and UKEX areas, zones 1, 2, 21 and 22. Operators connect an airline to power a pneumatic-hydraulic circuit which powers the lift, clamp, rotation and drive of the unit. Precise drive control is achieved using a sophisticated pneumatic-hydraulic control circuit.