We can now integrate heavy-duty weigh scales into our drum lifters when needed. A 2000kg load cell is fitted between the lift carriage and the head assembly to measure the weight of the drum and its contents. The load cell is designed to be very robust for use in industrial environments. The display is mounted to the rear panel on the head assembly and includes weighing features such as zero, tare, etc. The weigh scale system is accurate to +/- 0.1kg making it great for batch production and quantity-sensitive operations.

Key product features

Weigh scale system

Weigh scale system

Universal drum catch

Universal drum catch

We use this precision gripper on a variety of our products. Laser-cut from stainless steel in our UK manufacturing facility, the adjustable drum catch can connect to drums of different types, sizes, and materials. For a breakdown of the drums that are compatible with this product, view the drum suitability document below.

Stainless-steel ladder rack

Stainless-steel ladder rack

Our stainless-steel ladder rack allows you to adjust the position of the drum catch to accommodate drums of different heights. Just move the catch lower for shorter drums and higher for taller drums. For a detailed breakdown of the drum heights that are compatible with this product, please see the specification below.

Manual hydraulic pump

Manual hydraulic pump

The aluminium hydraulic pump supplies oil to a ram, this system lifts drums when the handle is pumped. A hand-operated lever provides precise control when a drum needs to be lowered to the ground or onto a pallet. We assemble our hydraulics by hand in our UK factory to ensure that each system is both clean and reliable.

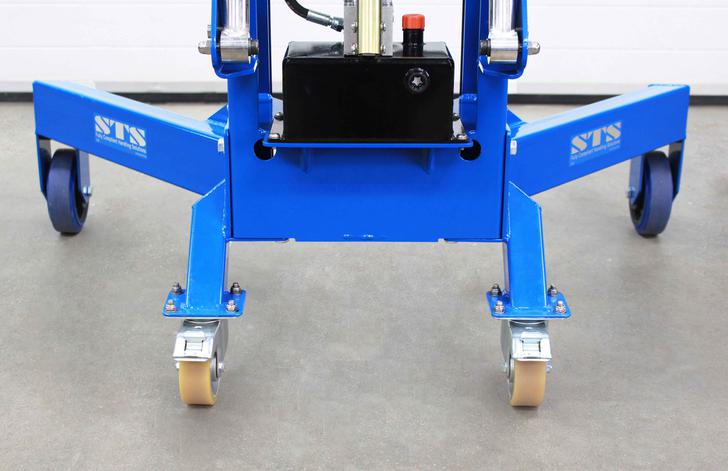

Chemical-resistant wheels

Chemical-resistant wheels

We source high-quality polyurethane wheels to ensure this product performs in all conditions. We also use precision bearings, which offer dependable wheel performance in harsh environments. To get the most out of this unit we recommend you use it on smooth surfaces.

Drum suitability

Drum suitability

The Corner Drum Lifting Trolley can handle a wide variety of drum types and sizes – especially useful if you handle different types of drums on a daily basis. For a detailed breakdown of the drums with which this product is compatible, please see the drum suitability document below. If the drums you use aren’t in the document, contact us and we can offer advice and guidance.

ATEX / UKEX-certified for Zone 1, 2, 21 and 22 (optional)

ATEX / UKEX-certified for Zone 1, 2, 21 and 22 (optional)

We can provide a fully-certified ATEX / UKEX drum lifting trolley for use in hazardous areas. The DTP05-R500-LC-Ex Corner Drum Lifting Trolley with Weigh Scale is designed and manufactured for use in gas and dust classified spaces: Zone 1, 2, 21, and 22. The drum lifter is constructed to ensure electrical continuity whereby a path to the ground is always present. A Declaration of Conformity is supplied which demonstrates compliance with the directives and relevant British and ISO Standards.

Specification

DTP05-R500-LC Weigh Scale Corner Drum Lifting Trolley

-

Safe working load (SWL)

350kg

-

Leg design

Straddle legs, internal width 1130mm, external width 1340mm

-

Pallet approach

Designed for lifting from the corner of a square pallet or from the end of a 800 x 1200mm Euro pallet

-

Drum compatibility

Steel, plastic and fibreboard drums, 50-220 litres (incl. MAUSER drums)

-

Drum gripping catch

Adjustable catch for different drum lips, catch is also height adjustable

-

Lift stroke

500mm

-

Under-drum clearance

370mm

-

Lifting system

Hydraulic 17cc hand-operated pump with lowering valve

-

Weighing system

Heavy duty weigh scale system with an accuracy of +/- 0.1kg. Weights are displayed on the fixed battery-powered display. Tare function available along with industry-standard weighing controls. A mains-powered battery charger for charging the display is provided.

-

Guarding

Shatterproof clear polycarbonate

-

Metal preparation

Grit blasted mild steel, aqua blasted stainless steel parts

-

Surface finish

Primer and polyester powder coated mild steel, stainless steel is smooth and clean

-

Unit colour

RAL 5010 (blue)

-

Front wheel type

Fixed 160mm, precision bearings

-

Front wheel material

Aluminium-centred, polyurethane tyres

-

Rear wheel type

Braked castors 100mm, precision bearings

-

Rear wheel material

Aluminium-centred, polyurethane tyres

-

Compliance

EC Machinery Directive 2006/42/EC

DTP05-R500-LC-Ex ATEX Weigh Scale Corner Drum Lifting Trolley

-

Safe working load (SWL)

350kg

-

Leg design

Straddle legs, internal width 1130mm, external width 1340mm

-

Pallet approach

Designed for lifting from the corner of a square pallet or from the end of a 800 x 1200mm Euro pallet

-

Drum compatibility

Steel, plastic and fibreboard drums, 50-220 litres (incl. MAUSER drums)

-

Drum gripping catch

Adjustable catch for different drum lips, catch is also height adjustable

-

Lift stroke

500mm

-

Under-drum clearance

370mm

-

Lifting system

Hydraulic 17cc hand-operated pump with lowering valve

-

Weighing system

ATEX heavy-duty weigh scale system with an accuracy of +/- 0.1kg. Weights are displayed on the fixed battery-powered display. Tare function available along with industry-standard weighing controls. The ATEX battery pack is to be charged outside of the ATEX area using a mains-powered charger.

-

Guarding

Anti-static shatterproof clear polycarbonate

-

Metal preparation

Grit blasted mild steel, aqua blasted stainless steel parts

-

Surface finish

Primer and polyester powder coated mild steel, stainless steel is smooth and clean

-

Unit colour

RAL 5010 (blue)

-

Front wheel type

Fixed 160mm, precision bearings

-

Front wheel material

Aluminium-centred, anti-static polyurethane tyres

-

Rear wheel type

Braked castors 100mm, precision bearings

-

Rear wheel material

Aluminium-centred, anti-static polyurethane tyres

-

Compliance

EC Machinery Directive 2006/42/EC

ATEX Directive 2014/34/EU

Zones 1, 2, 21 and 22 CE Ex II 2 G D

Optional features

ATEX / UKEX option

We can offer an ATEX / UKEX version of this model, suitable for use in zone 1, 2, 21 and 22 environments.Stainless-steel model

We offer a variety of stainless finishes suitable for clean rooms as well as good manufacturing practice (GMP) areas.Sale or return

In the UK we can supply certain equipment on a sale-or-return basis, meaning you can use a unit on-site for seven days with no obligation to buy it once the trial period is up. Find out more here.

Technical specification

Contact Us

Do you have a manual handling issue we could solve? We’d be happy to discuss any handling concerns and advise on the most suitable STS equipment. You can talk to us via telephone, email and social media.